Features:

- Ability to attach to any number of poly pipe fittings ie portable troughs, irrigation systems, animal/feeder/vehicle washdowns, spray tanks

- Each valve will fit multiple thread and connection combinations

- Strong Compact Design

- Delivers high volumes of water quickly with unrestricted full flow

- “Slipper Fit Piston” design to reduce valve sticking

- Low operating pressure required reducing pumping costs and increasing flow

- Mini body design to enable easy installation

- Manufactured from strong, non corrosive UV Stabilised materials

- Available in Female and Male BSPT, NPT, ACME thread configurations

- Suitable for High/Low Pressure operations (from 0.2 Bar to 12 Bar)

- Variable open and close action preventing valve bounce and water hammer

Overview

Hansen Super Flo Piston Valves have been designed with multiple thread and connection combinations. To increase overall durability and versatility, the 'slipper fit piston' design reduces sticking and increases efficiency. Less operating pressure is required reducing pump costs with increased flows. Mini body design allows for easy installation across a wide range of applications and the ability to operate in clean or dirty water.

TO CHANGE WATER LEVEL

Adjust the length of the cord at top of float

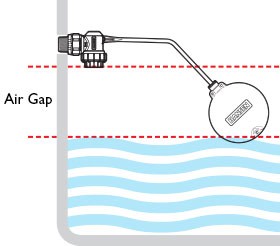

Side Entry Trough

- Thread Valve into existing trough fitting

- Screw the Nut with cord onto the Brass arm

- Thread cord through the float. Tie the cord off to achieve the correct on/off and water level

Trough Installation:

- Flush pipelines into water troughs before installing Valve into the new system

- Isolate the water trough to replace a valve in the existing scheme

- Thread O-Ring end of correct size male adaptor into the valve body and tighten firmly enough that the O-Ring creates a seal against the face. Do not overtighten.

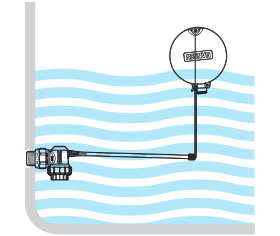

Top Entry Trough

- Thread Valve into existing

trough fitting - Screw the float onto the brass arm

- Hold the body of the valve at arm

entry point - Bend brass arm to achieve the

correct on/off and water level.